AUBURN HILLS – German automotive supplier Brose didn’t generate $6.5 billion in sales last year by relying on second-rate help.

For generations, Brose, parent company of Brose North America headquartered in Auburn Hills, has trained its 24,000-employee, highly skilled workforce using the touted German apprenticeship method. The concept is simple: Trainees alternate between classroom instruction and on-the-job training at a private company, gaining both practical and technical skills to compete in a global market.

Now, this time-tested program is gaining momentum in Michigan and helping to fill the pipeline with new, highly skilled talent.

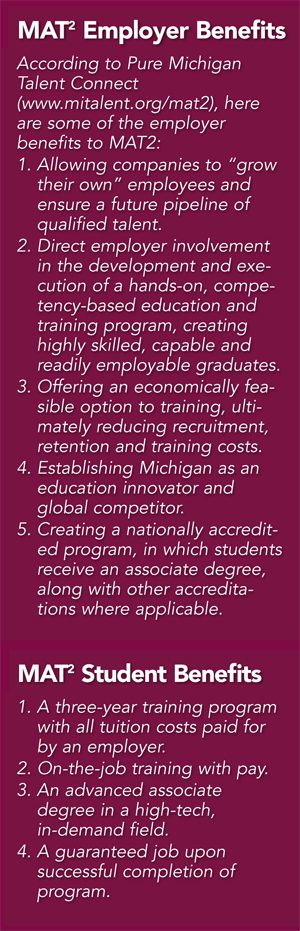

Officially known as Michigan Advanced Technician Training (MAT2), the program is designed by the state’s Talent Investment Agency (TIA). The aim is to address Michigan’s skills gaps in manufacturing by partnering high schools with community colleges and local employers. That is done by offering students apprenticeships that provide a path toward earning tuition-free associate degrees while simultaneously getting paid to gain on-the-job work experience in high-paying, high-demand manufacturing careers.

“Michigan has made tremendous economic progress, but we want that success to continue long into the future,” said Dave Murray, communications director for the Michigan Department of Talent and Economic Development. “We know that businesses locate or expand where they have access to talent. MAT2 is an example of one program that brings the business community and educators together so students get the education they need along with real-world, in-demand skills.”

Murray says the initiative is designed to address a historical phenomenon. “For too many years, Michigan parents had to watch their children leave the state to find jobs. Our tech and manufacturing sectors are growing, and will be vitally important as we continue as the national leader in autonomous and connected vehicles. That’s why programs like MAT2 are effective. Students are gaining the skills that are leading directly to jobs in the companies where they are being trained.”

In Michigan, employer demand for MAT2-type middle-skill workers – those with more than a high school diploma but less than a bachelor’s degree, such as largely technical jobs in manufacturing and health care—is soaring.

In Michigan, employer demand for MAT2-type middle-skill workers – those with more than a high school diploma but less than a bachelor’s degree, such as largely technical jobs in manufacturing and health care—is soaring.

The need for MAT2 graduates is likely to remain strong as baby boomers retire, with more than 5,700 job openings expected every year in Michigan through 2018. Average wages for full-time jobs in this arena are $23.37 an hour, compared with the living wage of $17.08.

Many of Metro Detroit’s largest manufacturers and industrial companies are participating in the MAT2 program, including American Axle, New Center Stamping, FTE, Pontiac Coil and Brose North America.

“Brose had four students who graduated this summer in the first class of MAT2 and we’re continuing to invest in it every year with 13 or 14 other students enrolled in the program right now,” said Michael Brosseau, Brose North America’s president. “It’s a great way to continue filling our talent pipeline.”

The idea for MAT2 began taking shape in 2012 when Gov. Rick Snyder toured the Brose Fahrzeugteile (“vehicle parts” in English) skilled-trades apprentice center in Warzburg, Germany. Since 2013, the program has grown from 11 to 45 companies that sponsor students through the three-year program that combines college classes with job experience. There are now 130 MAT2 students across Michigan, up from just 31 trainees when the program launched.

“MAT2 is ideal because it lets employers develop their own talent and gives students a great start to their careers. Thanks to the support of participating employers and colleges, MAT2 is having a direct and positive impact on our state,” Gov. Snyder said.

Demand surging for high-tech, middle-skilled workers

After suffering severe job losses from the decline of the auto industry and feeling the effects of the city of Detroit’s bankruptcy, metropolitan Detroit’s regional economy is stabilizing and employment is growing again, according to a JPMorgan Chase & Co. report published in April 2015 that focused on Wayne, Lapeer, Livingston, Oakland, Macomb and St. Clair counties.

But continued growth will depend heavily on the quality of its workforce.

“Investing in training will give job seekers of all ages the skills they need to open doors to economic mobility at the same time that it builds the skilled workforce that Detroit will need to thrive,” says Jamie Dimon, chairman and CEO of JPMorgan Chase & Co.

MAT2 is one of the ways the state of Michigan is addressing that need.

In its quest to train a globally competitive workforce, MAT2 addresses two critical issues facing the manufacturing and technology industries: a widening skills gap and an aging workforce.

Many skilled workers from the baby boomer generation are getting ready to retire and a lack of suitable applicants means their soon-to-be-vacant positions can’t be filled. Around 83 percent of U.S. manufacturers cannot find the skilled workforce candidates they need—a situation that projections show will result in about 3.4 million open positions by 2025.

“(Industries) know what a huge need there is for technically trained people who can install, troubleshoot and repair today’s highly automated manufacturing equipment,” said Deborah Bayer, dean of public services and CREST and interim dean of engineering, manufacturing and industrial technology at Oakland Community College.

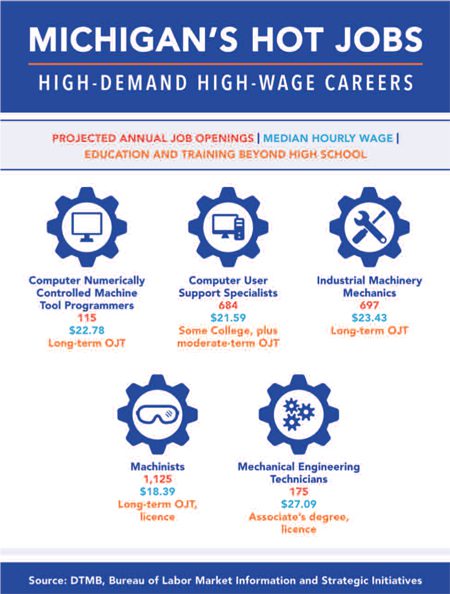

In southeast Michigan, for example, the metro Detroit region is expected to add nearly 700 jobs annually in occupations that need mechatronics training provided through Henry Ford College and Oakland Community College. Southeast Michigan will add more than 1,700 jobs annually in the IT field that OCC offers, while forecasts call for the region to add more than 450 jobs annually in occupations that need the computer numerically controlled (CNC) training available at Henry Ford College.

In southeast Michigan, for example, the metro Detroit region is expected to add nearly 700 jobs annually in occupations that need mechatronics training provided through Henry Ford College and Oakland Community College. Southeast Michigan will add more than 1,700 jobs annually in the IT field that OCC offers, while forecasts call for the region to add more than 450 jobs annually in occupations that need the computer numerically controlled (CNC) training available at Henry Ford College.

MAT2 is similar to other apprenticeship programs in that the employer selects the students, pays for their tuition while they are taking college classes, and pays them a wage while they are working.

Students spend three years alternating between classroom training at one of five community colleges and on-the-job, paid work experience. In return, MAT2 students are committed to remaining on the job for at least two full years.

The cost for the employer is about $22,000 annually, including tuition, wages and a $200 weekly stipend while in school.

While the investment is large, the return is worth it, said Mike Lueer, manufacturing supervisor at Flowserve Corp. in Kalamazoo. Flowserve’s 18,000 employees in 55 countries manufacture valves, pumps and seals; its Kalamazoo plant has about 400 employees.

Flowserve realized years ago that its aging workforce would be a problem unless new, qualified workers could replace them. That’s why Flowserve got in on the ground floor with MAT2 and sponsors two students enrolled in the CNC (Computer Numerical Control) program at Kalamazoo Valley Community College.

“We move them around the shop to give them a wide variety of things to do. Everywhere they’ve gone so far the operators themselves are really impressed with their work,” Lueer said.

Employer involvement guarantees a worker trained in their way of doing business.

In an effort to create more opportunities for workers and employers, federal and state agencies have dedicated new funding to grow apprenticeships.

Employers who register new employees/students with the U.S. Department of Labor may qualify for a one-time $5,000 grant for each student registered as a new apprentice.

‘A wonderful opportunity’

From where Jaime Van Hout is sitting, MAT2 is a perfect fit.

“You come out with an associate degree, no debt, a lot of knowledge and a guaranteed job that pays really good money…I don’t see any downside to that,” said Van Hout, a 20-year-old mechatronics technician apprentice for Brose North America.

Van Hout graduated in 2014 from Avondale High School in Auburn Hills. Her father, a retired mechanical engineer for Chrysler, had always told his children about the importance of technology. When she heard about the mechatronics apprenticeship program, she knew it was a great idea.

“Brose rotates me among different departments, so I’m learning so much. They’ve already sent me once to Germany and I’m supposed to return there this winter for more training. This is a wonderful opportunity,” said Van Hout, who will graduate this spring with an associate degree from Oakland Community College. She plans to pursue a mechanical engineering degree at night while continuing to work at Brose during the day.

The Michigan Talent Investment Agency, a select group of community colleges, and dozens of employers are now pushing to promote awareness of the MAT2 program to recruit more success stories like Van Hout.

“We want people to know an innovative new path exists in Michigan to obtain a tuition-free associate degree, paid for by a local employer, while getting on-the-job training with pay in a high-tech, in-demand field,” said Gary Saganski, associate dean of industrial technology at Henry Ford College.

Apprentices such as Van Hout and her peers train to become specialists in a variety of industries, including manufacturing, construction, agriculture, automotive and aerospace.

But in a country where university degrees may be considered by some to be the golden ticket to a comfortable life, the stigma associated with vocational schools remains in the minds of others.

Still, an expensive university education isn’t for everyone. The latest figures from the U.S. Bureau of Labor Statistics show that about 69 percent of high school graduates attend college. But a huge percentage of students who begin four-year college programs don’t complete them.

But many students—and their parents—still shy away from skilled trades not realizing real money and careers can be found there.

“Our challenge is that we have dozens of MAT2 apprenticeship openings in communities across the state, but we don’t have enough students applying for the program,” said Bayer of Oakland Community College.

Currently, the MAT2 program is offered only through the five colleges that are partnering with the state: Oakland Community College, Henry Ford College, Delta College, Kalamazoo Valley Community College and Baker College of Cadillac. However, state officials say they are hopeful that ongoing discussions with K-12 and community college administrators will lead to extending the initiative to more Michigan communities.

Students interested in applying for admission to the MAT2 program can apply in their senior year of high school. They must be high school graduates or have their GED and meet the college’s entrance requirements. Once approved for the program, applicants are interviewed by the sponsoring companies for final selection.

“These MAT2 apprenticeships are the entryway to cutting-edge careers in advanced manufacturing using 3-D models, computer simulations, software development and more in fields such as robotics and electronics,” Bayer said. “We just need more students to become interested in taking advantage of this incredible opportunity.”

Michigan apprenticeship totals among nation’s best

Mark Tomkins, president and CEO of the German American Chamber of Commerce of the Midwest, said the skills gap is a major obstacle when it comes to future investments in the United States. Tomkins said 69 percent of German companies have reported difficulties in finding employees with the adequate skills to expand their business.

materials, parts and tools to build an electronic device. Students from Henry Ford College work with their instructor at Oakland Community College. Photo by Michigan TED

Rather than look down at skilled trades, experts say the training system should be embraced.

“We have an entire generation of parents who have taught their kids that manufacturing is dirty. But it’s really a new world out there now,” Bayer said.

Germany has launched pilot programs all over the world to meet today’s skills shortage in manufacturing. In the Midwest, the German American Chamber of Commerce has partnerships with apprentice groups in Michigan, Illinois, Georgia and Kentucky.

In Michigan, the German American Chamber of Commerce of the Midwest is a member of the MAT2 Strategic Steering Committee.

In 2015, Michigan became the first state in the United States to receive approval from the German Chamber network for the alignment of its company consortium-based mechatronics apprenticeship training program to German standards.

Now, Michigan is one of the leading states across the United States with a 27 percent increase in registered apprentices during 2014-15, having more than 900 United States Department of Labor (USDOL) registered apprenticeship programs, and more than 12,000 active apprentices.

MAT2 student Phillip Bartko, who is 20 and just months away from becoming a technical product design technician, has no regrets from not choosing the university path.

“All my buddies that went away to different universities, state universities like Central Michigan, they’re coming out of college and they have no experience,” he said. “And when they go to get a job, it’s impossible because they don’t have any experience.”

Bartko says the path he is taking has none of those issues.

“By the time I’m a full-time employee I’ll have three years of school under my belt and no college debt.”